Eddy Current Principle

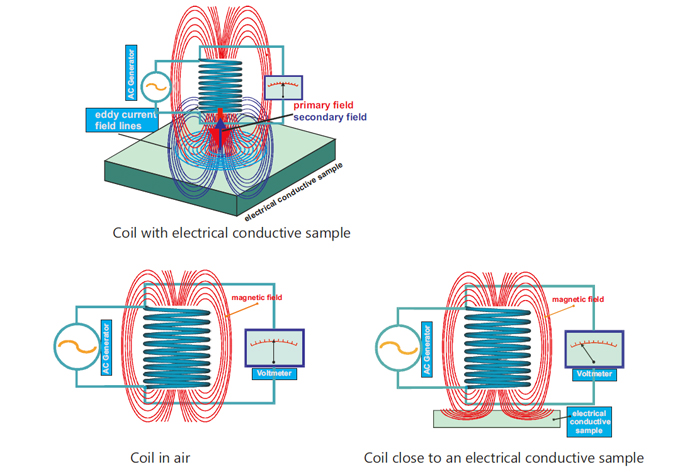

The eddy current method is based on the principle of generating circular electrical currents (eddy currents) in a conductive material. This is achieved by the use of a coil connected to an alternating current generator driving an alternating magnetic field (primary field). The current flow induced by this primary field within the conductive material will itself produce a magnetic field (secondary field) in opposition to the primary field according to Lenz’s law.

This reaction can be measured as a change of the impedance of the coil/sample arrangement (change in amplitude and phase of the voltage related to the generator current driving the coil). A coil in air is not influenced by eddy currents, but moving the coil towards an electrical conductive sample results in a signal, which can be used for distance measurement, e.g. measurement of non-conductive coating thickness on electrical conductive material.

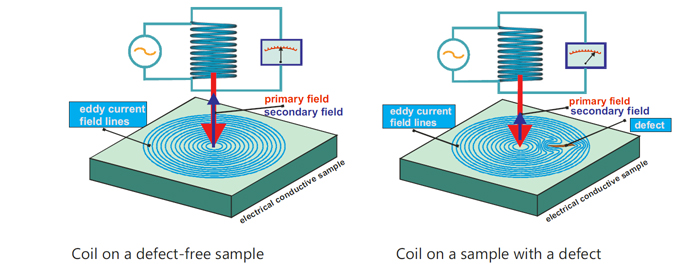

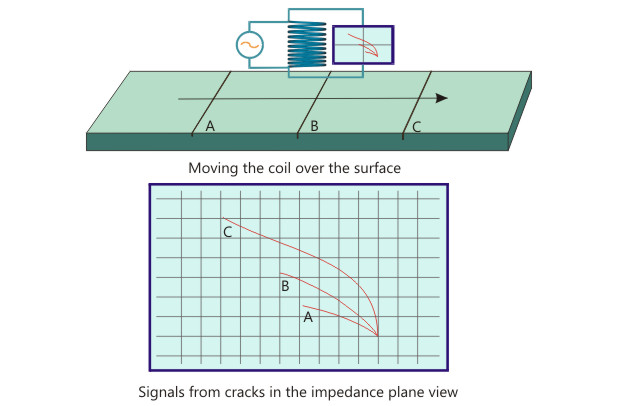

The eddy currents will always go the easiest way, and if cracks exist in the material, the current will go around the crack. This change of eddy current flow also can be detected by monitoring the impedance of the coil and is mainly used for detection of cracks.

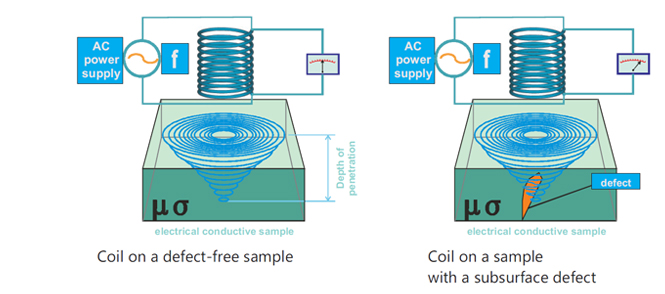

The eddy currents are flowing beneath the surface of the material with the highest density close to the surface. The depth of penetration of the eddy currents depends on the conductivity and permeability of the material and the frequency of the alternating field. At high frequencies the eddy currents concentrate at the surface, while with lower frequencies deeper regions within the material are penetrated.

By utilizing this on e.g. a sheet of aluminum, both, cracks on top of the sheet and on the other side can be detected. It is also applicable to detect subsurface corrosion and to determine the thickness of conductive sheets.

This effect is used mainly for non-ferromagnetic material. Due to the high permeability of ferromagnetic material the standard eddy current method here is limited to the region close to the surface. There exist extended methods to inspect e.g the subsurface of thick-walled ferromagnetic pipes or plates.