The remote field eddy current method

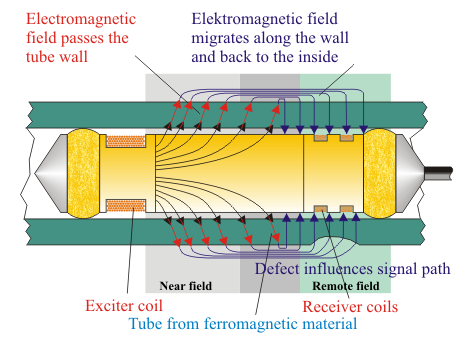

The remote field eddy current (RFEC / RFET) method can be used for inspection of ferromagnetic and thick walled non-ferromagnetic tubes. Against the magnetic bias eddy current method it has advantages in defect depth determination and detection of uniform tube wall thinning. The figure shows the working principle of the remote field eddy current technique.

The exciter coil is driven by a low-frequency alternating current. The generated magnetic field penetrates into the pipe wall and produces eddy currents. These eddy currents again generate a magnetic field, which counteracts the producing field, but also extends in the direction of the pipe outer surface and there again generates eddy currents. This process is repeated several times, so that a small part of the field penetrates the tube wall. Due to the antenna-effect of the tube this part of the field which has penetrated the pipe wall, runs along the outer side of the tube and constantly penetrates back into the tube. The primary field generated by the exciter coil attenuates within the tube. At a distance of about 2.5 times the tube outside diameter from the exciter coil, the primary field is no longer effective, so that from this distance on only the portion of the field is still effective, which has penetrated back through the tube wall.

Related to the distance from the exciter coil three areas can be distinguished. In the near field region the direct field from the exciter coil has a significant influence on the measured signal. In the transition zone the direct field and the field, which has penetrated the tube wall, have nearly the same amplitude and interfere with each other. In the far (or remote) field region only the portion of the field, which has passed through the tube wall, extending along the tube and re-entered the tube is effective. The receiver coil is placed in the remote field region, where the induced voltage in the receiver coil is generated only by the portion of the field which has penetrated the pipe wall twice. Depending on the wall thickness the phase of the signal changes and may be evaluated for determining the flaw depth, as it is known from conventional eddy current method.