Tube Inspection Methods

The application of electromagnetic methods is an accepted technique for checking the integrity of heat exchanger tubes. Due to the large number of materials, tube types and damage mechanisms selecting the optimal method of appropriate probe type and signal analysis mode, as well as the evaluation of the benefits and limitations of each method is important for optimal defect detection and inspection results.

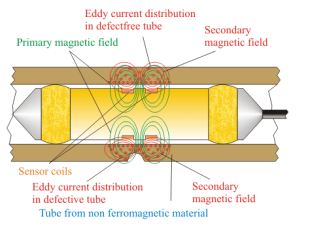

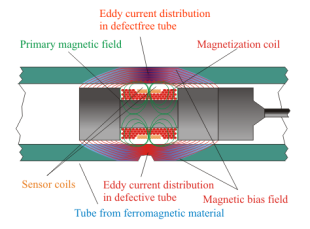

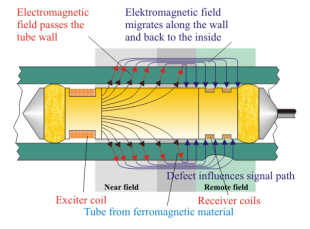

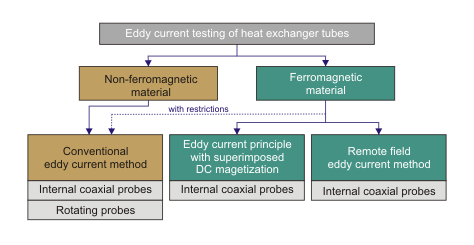

For the testing of heat exchanger tubes three variants of the eddy current methods exist (see figure)

● the conventional eddy current method

● the eddy current principle with superimposed DC field magnetization

● the remote field eddy current method

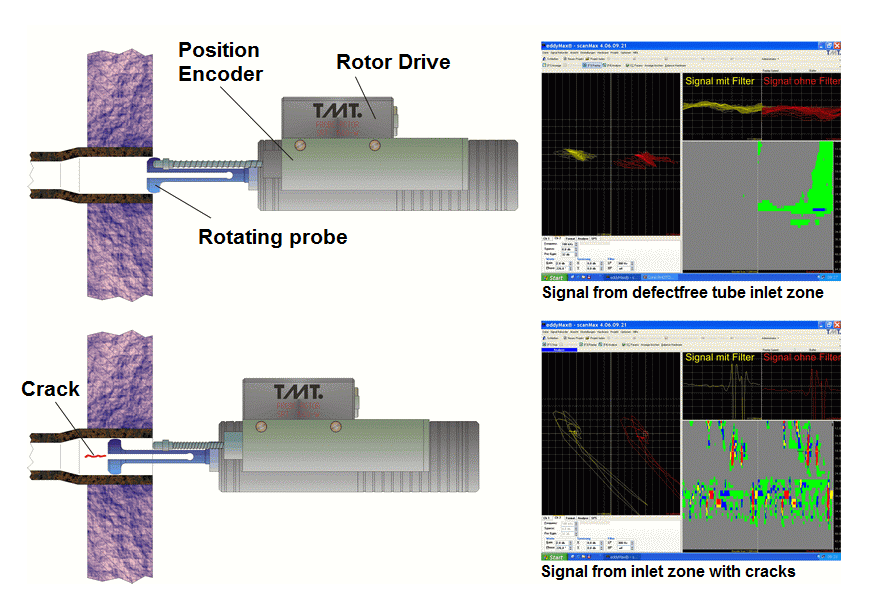

RotoScan RP-Method

• C-Scan inspection with rotating eddy current probes, for defect detection

in bore holes, pipes and tube expanded zones, within ferromagnetic and

non-ferromagnetic materials.

in bore holes, pipes and tube expanded zones, within ferromagnetic and

non-ferromagnetic materials.